In the 1950s, the United States transformed the “Brown Bear” cargo ship into a breeding boat, and built a simple steel cage for breeding silver salmon in the coastal waters, which can be regarded as a pioneer of equipment-based mariculture. It was not until the 1980s that Sweden and the former Soviet Union really began to develop steel deep-sea aquaculture equipment capable of cultivating fish in the harsh sea conditions. After that, the United States has developed various types of deep-sea aquaculture equipment. At present, Norway and China are at the forefront of the world in deep sea aquaculture.

The cultivation capacity of Atlantic salmon in the Norwegian fjord has become saturated and the disease of sea lice has become increasingly serious. Although the scale of Atlantic salmon cultivation has been expanding in the past few years, its cultivation cost has not decreased correspondingly. To this end, the Norwegian government is encouraging the development of Atlantic salmon aquaculture as a national pillar industry to the open sea by reducing the number of aquaculture cages in the fjord, rewarding the quota of open-sea aquaculture and other measures. Typical breeding equipment for Norway to open sea include semi-submersible “OceanFarm1” and ship-shaped cage “Havfarm”.

With the strong support of Chinese governments at all levels and the active participation of financial, equipment manufacturing and breeding enterprises, various innovative breeding equipment have been emerging in many coastal areas of China, such as “Deep Blue 1”, “Dehai 1”, “Jinghai 1”, “Blue Diamond 1”, “Penghu” and “Guoxin 1”. However, there are still some vague understandings about the development of deep sea aquaculture from all walks of life, which is not only detrimental to the healthy development of deep sea aquaculture industry, but also puts some deep sea aquaculture enterprises at greater risk. The following article briefly introduces the types of equipment, economic benefits, intelligent equipment, and integration with other new marine business forms.

3.1 Type of deep sea aquaculture equipment

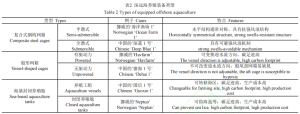

Many types of deep-sea aquaculture equipment have been developed by countries all over the world according to different types of aquaculture, sea conditions, and types of substrate. The distinctive feature of the far-reaching marine breeding equipment is that the framework is constructed of rigid materials, with automatic feeding and other systems, which can resist or avoid strong typhoons. These equipment can be simply divided into three categories: composite steel cage, ship-shaped cage and sea-based aquaculture tank (Table 2).

Composite steel cage usually has symmetrical structure in the horizontal direction, including semi-submersible and full-submersible structures; Boat-shaped cage is usually divided into multiple breeding units, including driving force and non-driving force structure; Sea-based breeding cabin includes a breeding boat with driving force and a closed marine breeding cabin without driving force. Some aquaculture structures are between the two types and can be classified according to their main characteristics.

Due to the asymmetry of the horizontal structure of the ship-shaped cage, when the ship is long and has no driving force, the cage unit at the stern of the ship is prone to hypoxia. For the ship-shaped cage with single-point anchoring and driving force, the upstream direction of the cage can be adjusted as needed to avoid the lack of oxygen in the tail cage, but this will additionally increase the energy consumption cost and the carbon footprint of the product. The aquaculture boat has the advantages of moving according to the water temperature and avoiding typhoons. The aquaculture practitioners in Norway also hope to reduce the infestation of sea lice by using closed aquaculture tanks. However, the equipment of sea-based aquaculture tanks generally need fuel oil to generate electricity to change water frequently to maintain good water quality in the tanks and reduce diseases. Therefore, the aquaculture cost and carbon footprint are high. There are many conceptual and tested sea-based aquaculture tanks in the world, but the number of them still in use is very small, which is related to the high investment, high breeding costs and high carbon footprint. It is the key to improve the market competitiveness of aquaculture craft products to give full play to the advantages of aquaculture craft moving by water temperature, cultivate suitable species, reduce the cost of fuel oil and purchase large size seedlings.

3.2 Economic benefits of deep sea aquaculture

The economic benefits of far-reaching marine aquaculture are related to the type of aquaculture equipment. In Norway, the cost of land-based recirculating water culture of Atlantic salmon is 43.6 NOK/kg (about 30 yuan/kg), the cost of cage culture in open sea area is 30.6 NOK/kg, and the cost of sea-based cage culture is 37.9 NOK/kg. The reason why the cost of aquaculture in open sea area is lower than that in land-based recirculating aquaculture is that the former utilizes the self-purification ability of the sea and avoids all or part of the cost of water treatment. In addition, cage culture also makes use of the role of natural sea current to supplement dissolved oxygen. Therefore, cage culture that makes full use of the ecosystem service function of the sea area is one of the most economical types of mariculture.

The economic benefits of far-reaching marine aquaculture are related to the scale of aquaculture. For a single cage, the larger the cage volume is within a certain volume range, the lower the unit volume cost is, but the size of the cage will be subject to the flow velocity and dissolved oxygen dynamics in the box, not the greater the cage, the better the economic benefits. In the process of aquaculture, the cage almost completely depends on the natural ocean current to exchange water and supplement dissolved oxygen. Therefore, the ocean current speed and dissolved oxygen level in the flat season with the minimum ocean current are the key factors that restrict the cage specification. When the cage size is large, the density of the animals should be reduced or oxygen enrichment equipment should be equipped. Because the deep sea aquaculture area is far from the shoreline, special functional ships for transportation, care management, fishing and other functions need to be equipped. Only when the number of aquaculture cages reaches a certain number, can the potential of these ships be fully utilized and the cost of aquaculture per unit output be reduced.

Compared with other mariculture methods, the investment in the construction of deep-sea aquaculture equipment is more and the production and management costs are higher. Therefore, in the current situation of coexistence of offshore aquaculture, deep-sea aquaculture and deep-sea aquaculture, the premise of achieving profits of deep-sea aquaculture can only be to breed those species of higher quality that are difficult to breed in ponds, offshore waters and offshore waters, or those species that can obtain additional benefits through deep-sea aquaculture. For example, the quality of the large yellow croaker cultured in China’s Far Sea is significantly better than that of the large yellow croaker cultured in the offshore, so the price of the former is also higher. For another example, “Deep Blue 1” can use the Yellow Sea cold water mass to cultivate salmon and trout that usually cannot spend summer in Chinese waters. Compared with Norway, the Chinese Yellow Sea Cold Water Regiment has the advantages of low logistics cost, short breeding cycle, low labor cost, good water quality and light sea lice disease. In addition, the breeding boats can be transferred to different sea areas with the seasons, and if properly arranged, the cultured fish can grow faster. More than 10% of the cost of cultivating Atlantic salmon in the fjord in Norway is used to prevent the disease of sea lice, while the density of sea lice in the far sea is low and the disease is light, so the cost of disease prevention in the far sea is low.

The rapid development of deep sea aquaculture in China benefits from the internal needs of industrial development, the active participation of equipment manufacturing enterprises and the strong support of the government. The active participation of equipment manufacturing enterprises is undoubtedly an important reason for the emergence of a large number of innovative deep-sea aquaculture equipment in China, but the application of some aquaculture equipment has not solved the problem of what kind to breed. The high construction investment and high production and management costs of far-reaching marine aquaculture determine that the use of these equipment to breed the species that local people can breed in ordinary ponds and ordinary cages usually does not have market competitiveness.

China’s aquaculture industry still has a lot of work to do in the selection and domestication of offshore aquaculture species. Some places in northern China are promoting the “fish farming in the south and north” model, which is actually a paradox in fish transplantation and domestication. The successful cases of “fish farming in the south and north” are usually geothermal resources or waste hot water resources of thermal power plants or other special factors, which are not universal. On the contrary, “fish farming in the north” and “fish farming in the south” are of universal significance. For example, coastal areas such as Fujian Province breed ginseng, abalone, algae and other species in the north in the low temperature season. China has also cultivated salmon and trout fish in the waters of the Yellow Sea Cold Water Regimen, which are also introduced from higher latitudes.

3.3 Intelligentization of deep sea aquaculture equipment

At present, many deep sea aquaculture equipment in China are often labeled as “intelligent”, but this is not the case. Intelligent aquaculture is an aquaculture activity implemented with the support of computer network, big data, Internet of Things and artificial intelligence. It is composed of “people-oriented” intelligence and “fish-based” intelligence. The former aims to meet the needs of people, while the latter aims to meet the needs of cultured fish. In recent years, the intelligent technology of Chinese ships and marine engineering equipment has made considerable progress. These people-oriented intelligent technologies have been transplanted into aquaculture, and there are basically no technical obstacles in the implementation of cage design, automatic feeding, real-time monitoring and processing of environmental parameters, automatic image acquisition and processing, biomass assessment, intelligent net washing, dead fish collection, etc. However, intelligent technologies based on fish behavior and physiological knowledge, such as intelligent feeding, intelligent oxygen enrichment, intelligent light supplement, intelligent disease detection and evaluation, and environmental hazard warning, are still far from practical application. The fish-based intelligence is the short board of the current deep and distant sea aquaculture intelligence. Only the experts in aquaculture, ichthyology, engineering and information technology can truly realize the intelligence of deep and distant sea aquaculture.

In the same way, relying on the technical accumulation of Chinese shipbuilding and marine equipment enterprises for many years, the safety of far-reaching marine breeding equipment against wind and waves can be well guaranteed. However, based on the behavior and physiological knowledge of fish, the air supply equipment for the swim bladder of the submerged fish, and the large cage batch on-demand fishing equipment have not been well solved.

3.4 Integration of deep sea aquaculture and wind power industry

In 1987, Bugrov, a scholar of the former Soviet Union, first carried out the cooperative operation of the open water fish farming equipment “Sadco Kitezh” and the oil exploitation platform in the Caspian Sea, which can be regarded as a pioneer in the cooperative production of aquaculture and energy industry. At present, although there is no consensus on whether the operation of wind turbines will affect the growth of cultured fish, western developed countries have generally accepted the idea of integrating offshore aquaculture with wind power and other industries. Research shows that the combination of mariculture and wind power can reduce the operation and maintenance costs of wind farms by 10%. The experiment of He (2015) shows that the net cage culture combined with the fan base can increase the income of fish farming by 44%. However, Jansen et al.

In western countries, wind farms can not only share the same sea area with aquaculture, but also produce fish reef effect, reduce the amount of anchor piles of shellfish culture floating raft, which is conducive to the development of fishing industry and shellfish culture. In China, although wind power can also share the sea area with mariculture, due to the underdevelopment of the fishing industry, wind farms are also far away from the coast. How to integrate the offshore and deep offshore aquaculture with wind power and other industries to produce significant complementary and mutually reinforcing effects still needs innovative models.

3.5 An innovative deep sea aquaculture model

Due to the implementation of strict environmental protection supervision, harbor regulation, coastal zone comprehensive management and other policies, China’s offshore aquaculture has begun to shift to offshore and offshore in a large scale, which undoubtedly brings important opportunities for deep and offshore aquaculture. However, the above analysis and the assessment of the research team show that the sustainability weight of China’s current far-reaching marine aquaculture system is not high. The main problems include large investment per unit of aquaculture volume, high aquaculture costs, low contribution rate to national food security (low total output), high biological footprint, and the inability to solve the problems of reemployment of fishermen whose offshore fish rafts have been banned. To this end, experts from China Communications Construction Co., Ltd. and China Ocean University put forward the development model of “marine fishing city”. “Marine Muyu City” is to build a huge aquaculture farm in the open sea by using wave prevention and current reduction facilities, in which common aquaculture facilities are used to carry out multi-nutrient level comprehensive aquaculture, mainly fish. Due to the huge scale of aquaculture, this model can not only produce a large number of green aquatic products, but also make it possible to integrate aquaculture, processing, logistics, wind power, tourism, etc.

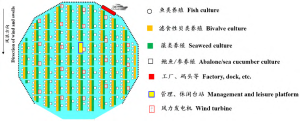

Take the designed “East China Sea Muyu City” as an example (Figure 1), with an investment of 10 billion yuan, a huge deep sea aquaculture space with a length of 10 km and an area of 8 km2 can be built, and the service life of the facilities can reach 100 years. In the farm, common deep-water net cages are used to mainly raise large yellow croaker and other fish, and floating raft facilities are used to comprehensively cultivate kelp, asparagus, oysters, abalone and other fish, so as to implement the integrated operation of aquaculture, processing, logistics, wind power, tourism and so on. Although the “marine fishing city” model has huge investment and is difficult to raise funds, its investment per unit volume is relatively small, its breeding cost is low, its fish quality is high, its environmental negative effect is small, it meets the requirements of the double-carbon target, and it is conducive to the re-employment of fishermen who have lost their rafts. It is a far-reaching marine aquaculture model with environmental protection, economic and livelihood benefits, and has significant economic, social and ecological benefits.