AQUACULTURE MOORING ROPE

BREAKING STRENGTH

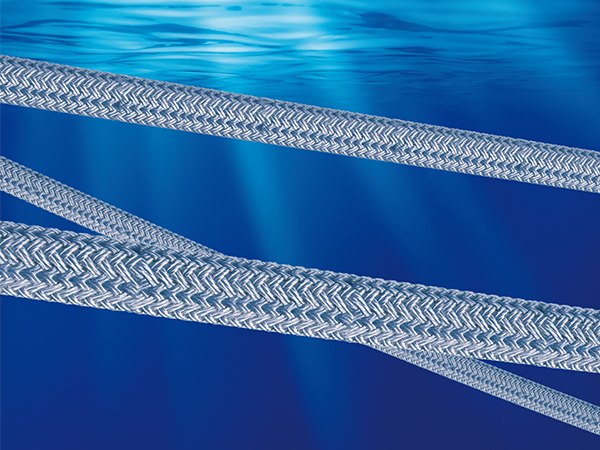

ULTRA HIGH MOLECULAR WEIGHT POLYETHYLENE ROPE

Ultra high molecular weight polyethylene(UHMW-PE) is polyethylene with a molecular weight of more than 1 million. Compared with other materials, it has the advantages of superb abrasion resistance, super high breaking tension, long service life and self-lubrication. The outer layer is made of polyester braided sheath, which enables it to filter out particles with diameter greater than 5μm from entering the rope in deep water and high pressure environments, and avoid shear damage to the rope body from particles.

BREAKING STRENGTH

| Size | Weight | Breaking Strength ISO | Breaking Strength MEG4 | ||||

|---|---|---|---|---|---|---|---|

| Mm Dia. | Inch Cir. | g/m | Kg/220m | KN | ton | KN | ton |

| 40 | 5 | 940 | 206.8 | 1140 | 116.3 | 1030 | 105.1 |

| 44 | 2005/1/2 | 1150 | 253 | 1380 | 140.2 | 1240 | 126.6 |

| 48 | 6 | 1360 | 299.2 | 1610 | 164.3 | 1450 | 148 |

| 52 | 2006/1/2 | 1600 | 352 | 1920 | 195.9 | 1730 | 176.5 |

| 56 | 7 | 1850 | 407 | 2190 | 223.5 | 1970 | 201 |

| 60 | 2007/1/2 | 2120 | 466.4 | 2520 | 257.1 | 2270 | 231.6 |

| 64 | 8 | 2400 | 528 | 2880 | 293.9 | 2590 | 264.3 |

| 68 | 2008/1/2 | 2720 | 598.4 | 3260 | 332.7 | 2930 | 299 |

| 72 | 9 | 3070 | 675.4 | 3630 | 370.4 | 3270 | 333.7 |

| 76 | 2009/1/2 | 3400 | 748 | 4020 | 410.2 | 3620 | 369.4 |

| 80 | 10 | 3750 | 825 | 4510 | 460.2 | 4060 | 414.3 |

| 84 | 2010/1/2 | 4125 | 907.5 | 4930 | 503.1 | 4440 | 543.1 |

| 88 | 11 | 4500 | 990 | 5350 | 545.9 | 4820 | 491.8 |

| 92 | 2011/1/2 | 4900 | 1078 | 5815 | 593.4 | 5235 | 534.2 |

| 96 | 12 | 5300 | 1166 | 6280 | 640.8 | 5650 | 576.5 |

BREAKING STRENGTH

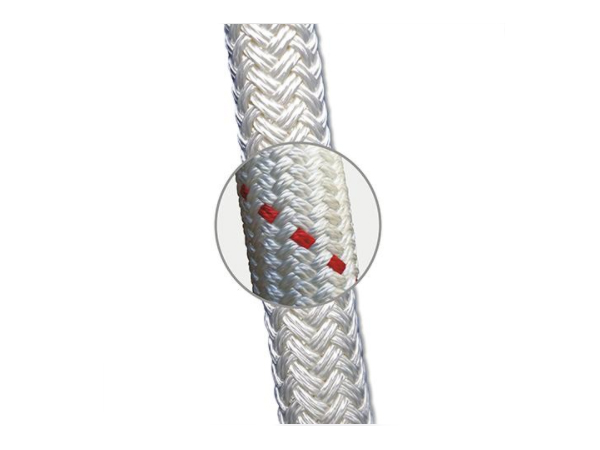

POLYESTER AND POLYPROPYLENE DOUBLE BRAIDED ROPE

Polyester polypropylene double-layer braided rope is made of high-performance polypropylene and polyester fiber mixed into a high-performance rope. It perfectly combines the advantages of the two materials and has the characteristics of high strength, high wear resistance, seawater resistance, chemical corrosion and low elongation. Our company adopts special mixed structure and technology, and the outer sheath is added for the rope to improve the wear resistance of the product. In the braiding process of the finished rope, the pre stretching technology is used to effectively reduce the residual deformation and prolong the service life of the rope.

| Size | Weight | Breaking Strength ISO | Breaking Strength MEG4 | ||||

|---|---|---|---|---|---|---|---|

| Mm Dia. | Inch Cir. | g/m | Kg/220m | KN | ton | KN | ton |

| 40 | 5 | 1050 | 231 | 315 | 32.1 | 283 | 28.9 |

| 44 | 2005/1/2 | 1282 | 282 | 375 | 38.3 | 338 | 34.5 |

| 48 | 6 | 1509 | 332 | 433 | 44.2 | 390 | 39.8 |

| 52 | 2006/1/2 | 1732 | 381 | 511 | 52.1 | 460 | 46.9 |

| 56 | 7 | 2091 | 460 | 581 | 59.3 | 523 | 53.4 |

| 60 | 2007/1/2 | 2350 | 517 | 659 | 67.2 | 593 | 60.5 |

| 64 | 8 | 2690 | 574 | 756 | 77.1 | 680 | 69.4 |

| 68 | 2008/1/2 | 2960 | 651 | 844 | 86.1 | 759 | 77.5 |

| 72 | 9 | 3310 | 728 | 932 | 95.1 | 839 | 85.6 |

| 76 | 2009/1/2 | 3696 | 813 | 1031 | 105.2 | 928 | 94.7 |

| 80 | 10 | 4082 | 898 | 1130 | 115.3 | 1017 | 103.8 |

| 84 | 2010/1/2 | 4471 | 983.5 | 1250 | 127.6 | 1125 | 114.8 |

| 88 | 11 | 4895 | 1069 | 1370 | 139.8 | 1233 | 125.8 |

| 92 | 2011/1/2 | 5350 | 1167 | 1500 | 153.1 | 1350 | 137.7 |

| 96 | 12 | 5750 | 1265 | 1630 | 166.3 | 1476 | 149.7 |

| 100 | 2012/1/2 | 6275 | 1380 | 1750 | 178.6 | 1575 | 160.7 |